Getting The Curve Radius Right on N Scale Layouts

To Avoid Potential Derailments of Model Trains

There is an old analogy scene in physics classes that demonstrates the nature of that force. If you swing a bucket full of sand on a rope around your head, the bucket will be traveling as some speed, and the rope will be pulling the bucket back as it attempts to fly off in one direction. That is the centripetal force required to keep the bucket going around in a circle instead of departing for parts unknown. If you lengthen the rope and swing the bucket so that the force is the same, the circle the bucket inscribes will be larger, and the bucket will have to move faster around the circle if it balances the force.

It’s the same with large radius curves on N scale model train layouts. The N scale model trains will have to travel much faster to overcome the centripetal force, so high speed mainline curves will have huge radii…700 or more feet. With N scale layouts, this is becomes a curve radius of about 53”.

There is an old analogy scene in physics classes that demonstrates the nature of that force. If you swing a bucket full of sand on a rope around your head, the bucket will be traveling as some speed, and the rope will be pulling the bucket back as it attempts to fly off in one direction. That is the centripetal force required to keep the bucket going around in a circle instead of departing for parts unknown. If you lengthen the rope and swing the bucket so that the force is the same, the circle the bucket inscribes will be larger, and the bucket will have to move faster around the circle if it balances the force.

It’s the same with large radius curves on N scale model train layouts. The N scale model trains will have to travel much faster to overcome the centripetal force, so high speed mainline curves will have huge radii…700 or more feet. With N scale layouts, this is becomes a curve radius of about 53”. The Right Couplers, Wheelset Flanges, and Curve Radius Can All

Help Keep N Scale Trains On The Track

Another factor is the placement of couplers on the cars. Prototypical rolling stock uses body mount couplers which have a fairly limited range of motion in which to remain joined. If the lateral forces are too strong, as would be the case when two adjacent cars go around a short radius curve, the couplers are likely to separate and even possibly be damaged. Although a model train will probably not be damaged, the likelihood of inadvertent uncoupling is greatly increased. In a similar fashion, trying to couple two cars on a curve requires that the couplers be fairly closely aligned. This is difficult, if not impossible on a very short radius curve. In the model world, truck mounted couplers and large-swing body mounted draft gear boxes can alleviate this somewhat, but if you are after true realism, you are probably strongly influenced to use body mounted prototypical couplers rather than truck mounted.

The third factor is the tendency of rolling stock to follow a straight line with the pulling force. You can demonstrate this with a piece of string on a table. If you put a small curve in the string and then pull on one end, the string will try to straighten out in response to the force. N scale rolling stock will do the same on a curved section of track.

The pulling force will try to make the car follow a straight line, which will make it try to derail on a curve. Ordinarily, the wheelset flanges will prevent this, but if the force is at too large an angle from the center line of the car, as is the case on a short radius curve, the car will literally be pulled off the track. There is nothing more frustrating than to have a train fly off the track and potentially be damaged. This problem is not confined to N scale model trains or N scale layouts, it can happen with HO scale, Z scale, OO gauge, or even the much bigger O scale trains.

Also, rolling stock length enters into the equation, at least at model scale. Very sharp curves will cause the corners of adjacent long wheelbase cars to get very close to one another. If the track curve is sharp enough, the corners will collide and the cars will derail. 80 foot passenger cars are particularly notorious for this, and for contact between the diaphragms on the end of the car. Long automobile and container stack carriers are also susceptible to interference. Real railroads do everything possible to avoid derailments as they can be costly and time wasting. The same applies to N scale model trains… damage caused by derailments can be costly in both money terms and with fixing the problem. Care should be taken when planning the track work with n scale layouts, just as it would be when a railroad company lays real-size train tracks.

N Scale Locomotive Wheelbases and Scale Curve Radius Requirements

Locomotive wheelbase is also an important consideration. Many long wheelbase n scale locomotives will simply not operate smoothly, if at all, around short radius curves. In the era of large steam, articulated locomotives such as the Challenger and Big Boy were designed to deal with this very limitation on existing rights of way.

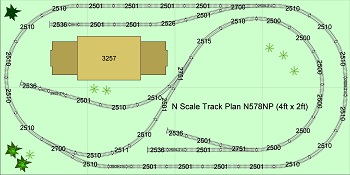

This photo illustrates long passenger cars on short radius curves.

N scale layout plans on a 4ft x 8ft baseboard is popular with n scale model railroaders worldwide.

This is not to say that your equipment will always have trouble on short radius curves. Modern manufacturers have done such things as undercutting lower body detail to allow longer coupler and truck swing to improve operation. On the other hand, when you try to run long wheelbase modern rolling stock on very short radius curves, realism suffers!

Scale Curve Radius | Corresponding Prototype Curve Radius | Corresponding Prototype Curve Radius |

Inches | Inches | Feet |

9.75 | 1560 | 130 |

10 | 1600 | 133.3333333 |

11 | 1760 | 146.666667 |

11.25 | 1800 | 150 |

12.5 | 2000 | 166.6666667 |

13.75 | 2200 | 183.3333333 |

15 | 2400 | 200 |

16.25 | 2600 | 216.6666667 |

17.5 | 2800 | 233.3333333 |

18.75 | 3000 | 250 |

19 | 3040 | 253.3333333 |

20 | 3200 | 266.6666667 |

21.5 | 3440 | 286.6666667 |

30.7 | 4912 | 409.3333333 |

71 | 11360 | 946.6666667 |

Common N Scale Sectional Track Radii

Many of the track plans in the downloadable N SCALE TRACK PLANS BOOK are for layouts built on 2 to 4 foot wide benchwork. In practical terms, the best you can do on a 4 foot width with some safety margin is about a 22” radius curve. Remember that in order to do a 180 degree turn you have to build out at twice the curve radius. This will accommodate almost anything you want to operate on the layout, however, and there are tricks that you can use to make N scale curves look more realistic. For example, if you arrange your scenery so that your shorter radius curves are always viewed from the inside of the curve, the longer wheelbase rolling stock will look better than if the curve is viewed from the outside. This is where planning plays an important part when designing and building n scale layouts.

The National Model Railroad Association has some recommended standards for curve radius that are worth reading. There is also a quick and dirty concept that you can use to determine appropriate curve radius. If you measure your longest car or locomotive from the end of the couplers, try to create a radius 3.5 to 5 times the length of that car. 3.5 is a compromise of best operation and reasonable appearance, 5 can look and operate prototypically. On n scale layouts you shouldn’t create curves of less than 2 times the length of that car. At twice the length, the curve radius will probably allow shorter wheelbase equipment to operate adequately, but that’s about the limit. The curves will probably not look prototypical from any angle. If your layout space is severely restricted, you may want to consider modeling timber, mining, or short line railroads, or railroads from an early era. These all have rolling stock that is much shorter than today’s high speed large equipment.